March 2023

|Last updated:April 2024

Can EV batteries be recycled?

In 2022, the UK saw a record 267,203 EVs registered (40% more than 2021 registrations). This equates to roughly 16% of all new cars sold in the UK (2022) and brings the total UK EV sales to around 669,000 - incredible!

But with EV adoption quickly gaining momentum, the question remains: how sustainable is an electric vehicle when it is no longer suitable to drive?

To celebrate Global Recycling Day 2023, this blog is going to explore the recycling process of the EV’s powerhouse, the lithium-ion battery, and what new processes we can expect to see developed in the coming years.

Let’s get plugged in…

What’s the current life expectancy of an EV battery?

When electric vehicles were first acknowledged as a viable alternative to petrol cars, there were some discussions concerning lithium-ion battery durability. IPhone batteries were famous for their rapid degradation, and the assumption was that EVs would follow this pattern. It was soon discovered however, that an EV’s battery capacity would only drop by 2% or so each year - the rate falling much slower than anticipated.

Luckily, EV batteries are made up of lots of individual cells and therefore, if defective, can often be replaced or repaired! Many manufacturers also offer warranties, guaranteeing their EV’s battery capacity - claiming it will maintain a 70% battery capacity for seven to eight years.

Whilst improvements to EV batteries are regularly being made, their lifespan is still typically around 10 years.

So, what happens to the battery when its time is up?

Thankfully, due to regulations, EV batteries are banned from landfills. The incineration and disposal process has been prohibited and thus the battery begins its second life!

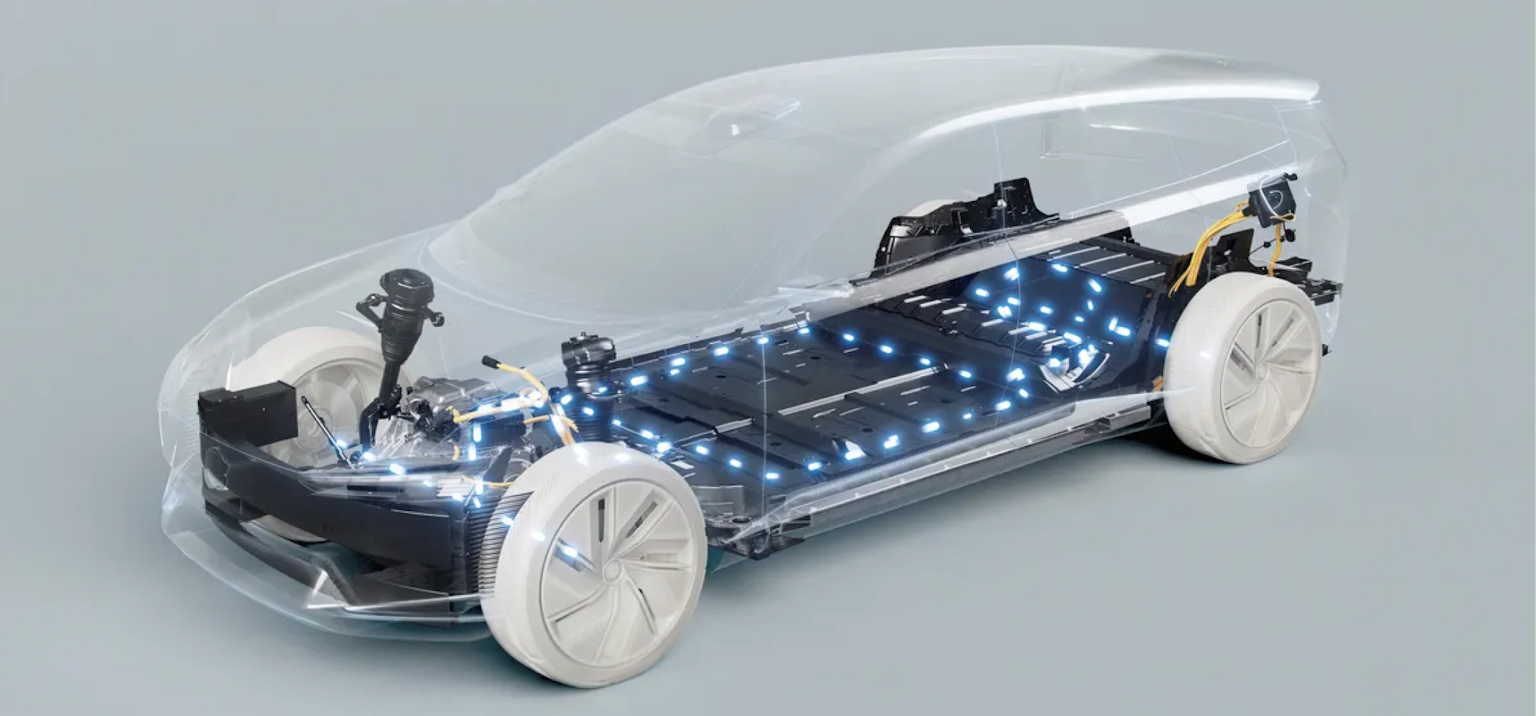

Despite being unable to provide a charge capable of running an EV, there is usually around 80% of usable charge capacity left in the battery that can be repurposed. At the end of its life in an EV, each battery is awarded a grade to determine its efficiency, indicating its capability and therefore whether the battery is for recycling or repurposing.

If the EV battery is graded for repurposing, it will typically be used for secondary energy storage uses such as power packs or solar energy repositories. Almost all EV manufacturers are taking individual approaches towards recycling their EV batteries. Nissan, for example, repurposes their EV batteries in their factory delivery vehicles.

In a recent project, Nissan also utilised 280 old EV battery packs to work as backup power for the Amsterdam ArenA (the home of Ajax FC); designed to absorb renewable energy when demand is low and to feed that energy back into the grid when necessary. Nissan’s project with used battery packs could be the start of a brighter future for battery recycling, as using these batteries to store clean, sustainable energy could help power the grid on a large scale!

Although repurposing is the most sustainable way to recycle EV batteries - maximising usage and aiding the grid - batteries can get damaged and therefore not all can be reused.

What happens if a battery cannot be repurposed?

When an EV battery is damaged, or has irreversible battery degradation, its cells will not be able to be used in a second-life project and will be sent to a recycling facility, where the metals and minerals will be extracted for new EV batteries.

Recycling old materials rather than mining new ones sounds like a flawless plan, but it’s a complicated process:

Firstly, battery packs are encased in steel, welded shut, and must be safely cracked open before the cells are moved (this must be done with care as it can result in fires or explosions if damage is done to the cells). Then, the materials are extracted in one of two ways: shredding and smelting or dissolving it in acid.

Shredding and smelting is the cheaper option and is therefore more commonly used, unfortunately it is not the most efficient process as materials are lost and the process is powered by fossil fuels. Using acid is more expensive but preserves a lot more of the material, however it consumes a lot of energy and produces toxic gas and wastewater. It is estimated that 500,000 gallons of water is required to extract one tonne of lithium.

Don’t panic - look to the future!

Whilst EV battery recycling has still got a way to come, there are some positive developments in the near future to look forward to.

Single(solid)-state batteries are an exciting new development, expected to massively outlast lithium-ion batteries and remain at peak optimisation for around 30 years! Although these single-state batteries are still in the works, research is being done by big manufacturers.

QuantumScape is a battery manufacturer, they're researching and developing solid-state batteries. Here are some benefits of solid-state batteries according to QuantumScape: they're more energy and cost efficient, they charge faster, have a longer lifespan and they're safer. Despite all these positives, QuantumScape isn't expected to deliver production-ready prototypes to its clients before 2025 and there’s no guarantee when solid-state batteries will be consumer-ready, but remember to keep an eye out as the future of EV batteries is coming soon!

To learn more about single-state batteries, check out our blog: How do EVs work?

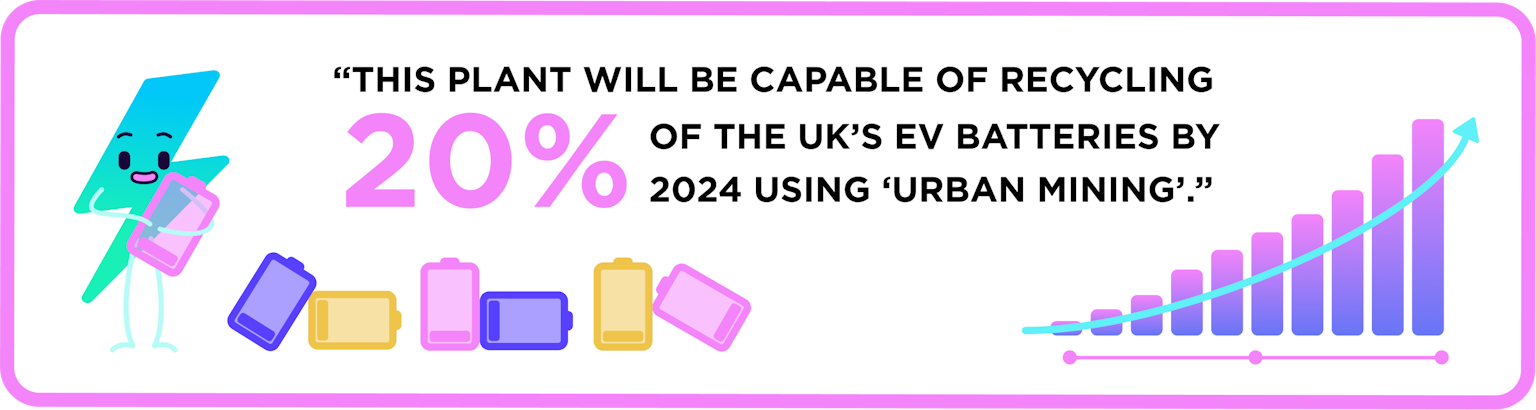

Additionally, Veolia has announced its first EV battery recycling plant in the UK, the new process protects the materials through chemical extraction, reducing emissions and water consumption by up to 50%! This plant will be capable of recycling 20% of the UK’s EV batteries by 2024 using ‘urban mining’. Veolia also has battery recycling specialists on hand, to help ensure the EV batteries are safely packaged, transported, and recycled.

Alternatively, Professor Gisele Azimi, of the University of Toronto Engineering’s Laboratory for Strategic Materials, has developed a more sustainable electric car battery recycling technique. This new technology could alter the method of EV battery recycling as we know it, helping secure a supply of critical metals. This process involves a supercritical fluid extraction for metal recovery; using fewer chemicals and generating significantly less secondary waste.

“The advantage of our method is that we are using carbon dioxide from the air as the solvent instead of highly hazardous acids or bases… carbon dioxide is abundant, cheap, and inert, and it’s also easy to handle, vent, and recycle.” - Azimi

Feeling enlightened or do you think something was missing? Let us know by sharing your feedback.

Interested in learning more? Head over to our Electroverse community area for more electrifying content.