April 2022

|Last updated:June 2024

The Life of an EV Battery

When we say ‘EV battery’, what's the first question that comes to mind? How much charge can it hold? How old is it? How far can it take me?

Fair enough, all good questions. But do you ever consider the lifecycle of an EV battery? How were the materials mined? Or what happens once the battery dies?

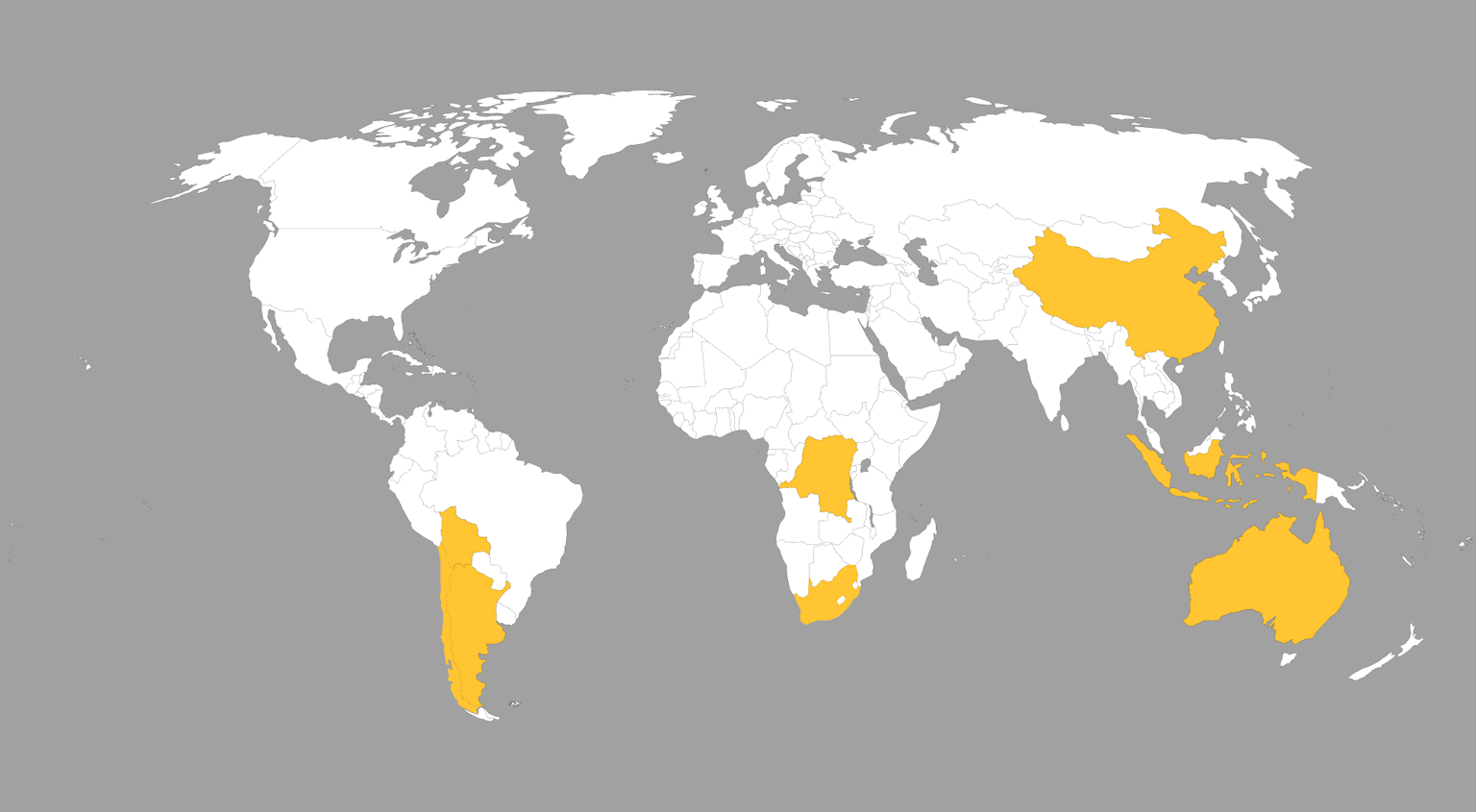

The lifecycle of an EV battery is a fascinating story and one that takes place from around the globe. For the purposes of this blog, we'll be talking about the lithium-ion battery, which is the most common battery type found in EVs.

Let's get plugged in...

Mining and Refining

It won't come as any great surprise, but lithium-ion batteries don't grow on trees. It would be very handy if they did.

Lithium-ion batteries are the product of several raw materials that have been mined and refined into the chemical compounds that make them work.

The five raw materials critical for EV batteries include lithium, cobalt, graphite, nickel and manganese. Unfortunately, these materials aren't found in the same location: lithium is mined in Chile, Argentina and Bolivia, cobalt from the DRC, graphite from China, nickel from Indonesia and Australia, and manganese from South Africa.

Cosmic Fact! Due to the amount of water consumed to extract the material, lithium mining has drawn some criticisms in the past, but with new processes (like direct lithium extraction) in development, it shouldn't be too long before lithium mining has little impact on water consumption or the environment.

It's worth noting that although lithium is mined in Chile, it's not refined in Chile - the same goes for other raw materials too. As China controls around 80% of the global raw materials refining process - and as the largest producer of graphite - nearly all EV battery compounds are refined in China.

Although China will likely dominate this process for a while longer, important research into sustainable mining is happening closer to home...

In the UK, a Cornish-based company called Imerys British Lithium has been researching the possibility of producing lithium from the mica in granite (of which there is plenty in the UK). In January 2022, it was announced that this had been achieved at a pilot level. This marks huge progress in the sustainability of lithium mining, as British Lithium becomes the first producer in the world to quarry and refine lithium at one site.

Manufacturing and Charging

Once the raw materials have been mined and refined, they are sent to a battery manufacturer to be assembled into battery cells and linked into modules.

Lithium-ion battery cells are assembled to contain an electrolyte and two types of electrodes: anode and cathode. Due to their remarkable ability in storing lithium ions (energy) when charging, these electrodes are the primary reason why lithium-ion batteries are used in EVs.

Cosmic Fact! When an EV battery charges, the electrolyte transfers the charged lithium ions from the anode to the cathode - it’s through this process that electricity is created! When an EV is being driven (or using power) the reverse happens.

Once the cells are linked into modules, they are sent to the production line to be packaged into battery packs and sealed in a protective casing with thermal sensors and a cooling system. The encased battery pack is subjected to a lot of safety tests, such as seal testing (to ensure the casing is properly sealed) and a series of electrics tests (to ensure voltage parts and insulation are working). If it passes the tests, a safety warning label is affixed, and it is sent down the production line to be fitted into the EV body.

To learn more about the make-up of EV battery cells and modules, and how the batteries charge, check out our blog: How do EVs work?

Recycling and Repurposing

When an EV battery comes to the end of its life (typically around 10 years), it doesn't end up in a landfill. Thankfully, regulations ban the incineration and disposal of EV batteries in landfills. So, what does happen?

When an EV battery dies, likely, there is still some charge capacity - not enough to power an EV - but enough for other energy storage purposes. Depending on the battery condition, it is awarded a grade to indicate its efficiency. These grades will determine whether the battery is for recycling or repurposing.

If an EV is graded for repurposing, this typically means that the battery will be used for secondary energy storage uses, such as power packs or solar energy repositories. While this effectively gives an EV battery a second life, the options for secondary battery use are currently limited, but not for long! EV battery technology is growing more powerful year on year - and with exciting developments like solid-state batteries on the horizon, second-life uses for batteries will also grow. The most exciting of these possibilities? Sustainable grid management. This would mean that used EV batteries would store clean energy, powering the grid during peak usage.

Want to learn more about solid-state batteries? Check out our blog: How do EVs work?

While repurposing is hugely beneficial to EV battery sustainability, not all batteries can be repurposed. So, what then? It's off to the recycling plant to extract the metals and minerals for new EV batteries.

While in theory, recycling sounds ideal - less dependence on mining new materials, less waste etc. - it isn’t as straightforward as it sounds.

As battery packs are typically welded shut, the steel casing must be safely cracked open before the cells are moved (this can be a dangerous process as damage to the cells can cause accidental fires or explosions). Once the pack has been safely dismantled, the cells are processed to extract the materials. This happens in one of two ways: shredding and smelting or dissolving it in acid.

The first option is most common as it is relatively cheap, unfortunately, it loses a lot of the materials in the process and is powered by fossil fuels. The second option is more expensive, preserves a lot more of the material, but consumes a lot of energy and produces toxic gas and wastewater.

Cosmic Fact! It is estimated that over 2 million litres of water are required to extract one tonne of lithium using these types of mining.

It's true: battery recycling has some way to come. Fortunately, there have already been positive developments in this area.

In January 2022, resource management company, Veolia, announced its first EV battery recycling plant in the UK, capable of recycling 20% of the UK's EV batteries by 2024 using 'urban mining'. This process protects the materials through chemical extraction, reducing water consumption and emissions by up to 50%.

In addition to 'urban mining', another development was announced in 2021 by the Faraday Institution. By using ultrasonic waves, the research team discovered that materials are extracted 100 times quicker than traditional processes, resulting in a higher purity of recovered materials. With this discovery, the research team are now working alongside battery manufacturers and recycling companies intending to license their technology and bring ultrasonic recycling to the market.

These achievements come off the back of the Faraday Institution Battery Challenge, which looks to support world-class research into developing world-class, efficient and safe battery packs by 2035. The goal: create an EV that is at least 95% recyclable.

Just watch this space...

Feeling enlightened, or do you think something was missing? Let us know by sharing your feedback.

Interested in learning more? Head over to our Electric Universe Community area for more electrifying content.